Almen strips are key tools for measuring energy in the blasting process. This article will help you understand how Almen tapes work, the technical differences between the different types and how to choose the right one for your blasting process.

What are Almen strips and how do they work in blasting?

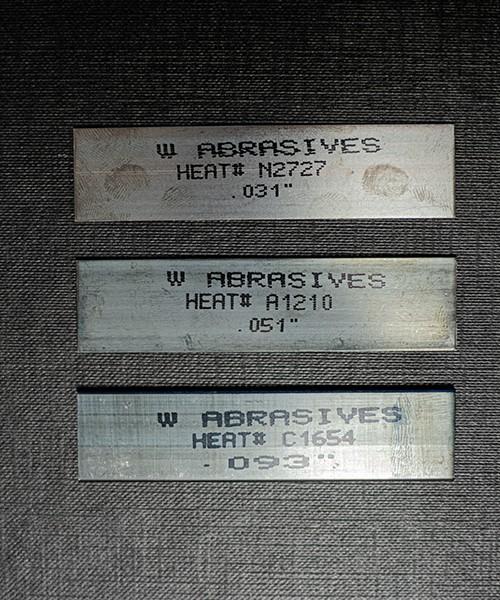

Almen strips are important measuring tools used to ensure accurate blasting intensity settings. During the blasting process, the tape deforms in response to the energy hitting the surface. The resulting deformation (arc height) is measured using an Almen Gage. Correct arc height ensures that the process meets stringent engineering or customer specifications.

Almen strips are universally applicable regardless of the type of media. For more information on the different types of blast media, visit W Abrasives' blast media offering.

Types of Almen strips

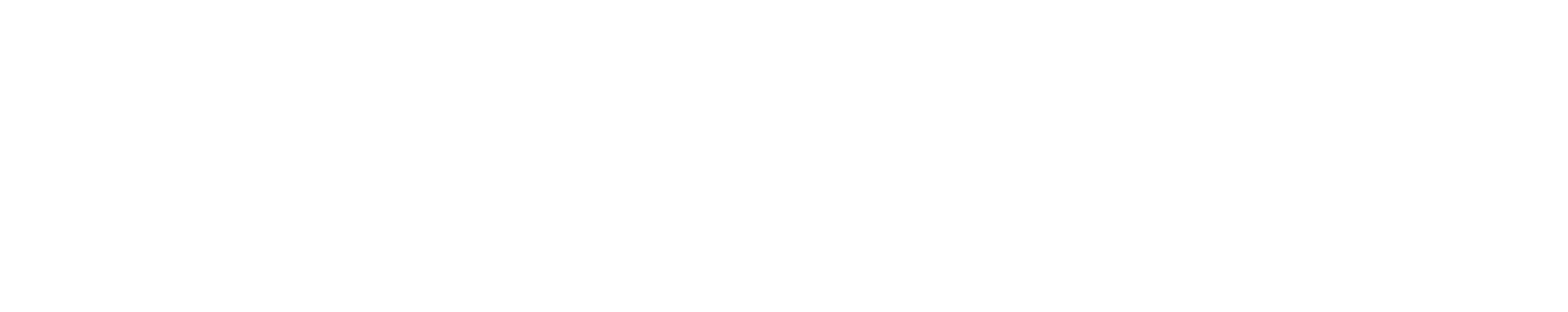

N-type Almen strips

The thinnest and easiest to deform N-type strips are used with very fine shot media. They are usually recommended for use with shot less than 0.5 mm in diameter. They are used where shot size is small and shot intensity is lower, making them ideal for fine or finely detailed parts.

A-type Almen strips

The most widely used and versatile type. They are used for media sizes from 0.5mm to 1.4mm and cover most shot blasting applications. If the arc height after blasting is less than 0.1 mm, use the N-type for greater sensitivity. For higher deformation (above 0.6 mm), switch to C-type.

If you need more powerful media for higher blasting intensity, check out the range of steel shot suitable for different types of applications.

C-type Almen strips

C-type strips are the thickest and most resistant to deformation and are designed for use with larger shot sizes, typically greater than 1.4 mm in diameter. These tapes are used in high-intensity surface hardening applications where significant energy is required, often for large and heavy components.

Certification and standards for Almen strips

There are three levels of certification: standard, certified 2 and certified 1 strips. Certified strips provide greater control over material properties and ensure higher measurement accuracy.

How do I choose the right type of Almen strips?

The choice of Almen strip depends on the engineering specifications and the required blasting intensity. Proper selection and use of Almen strips is critical to achieving desired results and extending the life of treated parts. For more information on media specifications and proper selection, see the technical information on the W Abrasives website.

Tools for Almen tapes.

Special tools such as the gauge and holder for Almen strips are used for accurate measurement and easy handling of Almen strips. These tools ensure consistent placement and accurate measurement of blasting intensity.

- Almen Gage: Used to accurately measure the arc height after the tape has been deformed. Click here for more information.

- Almen Strip Holder: Allows safe and easy handling of strips during placement and after blasting. Details about the holder can be found here.

If you have further questions or need a professional consultation, give us a call.